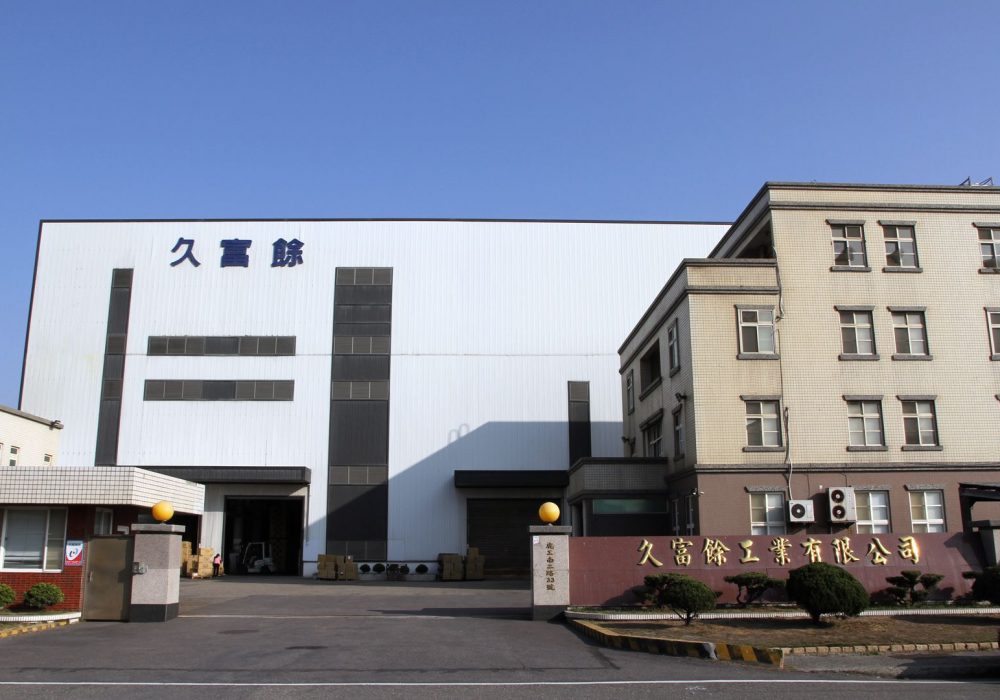

Chiufuyu Industrial Co., Ltd.

History

- CFY was founded in Xihu Town in 1994, with a factory building of only 100 square meters, 5 employees, and production of boxed facial tissues.

- The original plant was expanded to 200 square meters in 1999.

- The original factory was expanded in 2006, covering a total area of 1,800 square meters. It also purchased 12 million more toilet paper processing equipment and invested in toilet paper production.

- In 2009, an additional 40 million automatic toilet paper processing equipment was purchased.

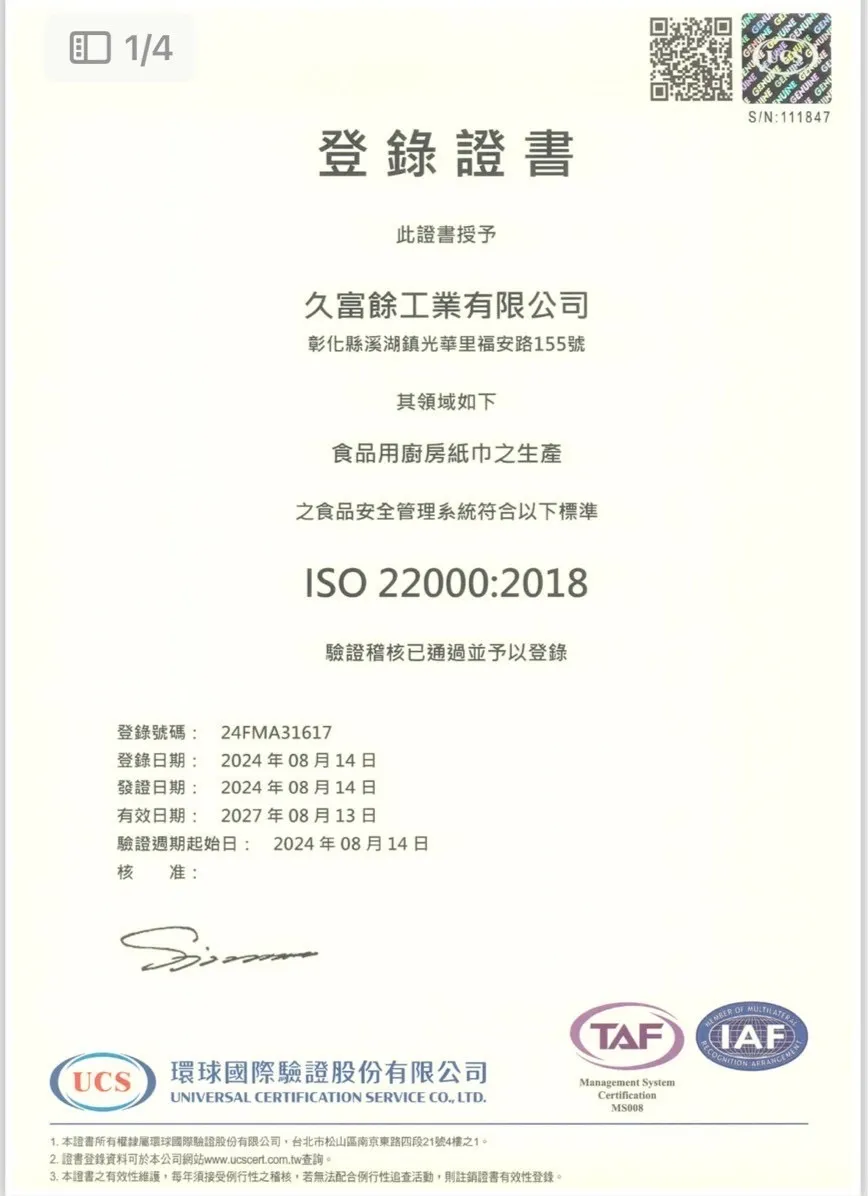

- In 2011, ISO 9001 was introduced.

- In 2014, a new Hemei factory was established, covering an area of 700 square meters.

- In July 2017, the two factories moved to the current location in Zhangbin, with a total floor area of approximately 6000 square meters. Add 60 million fully automated extraction production lines. The basic production capacity is 1,500 tons, and the maximum production capacity is 2,100 tons.

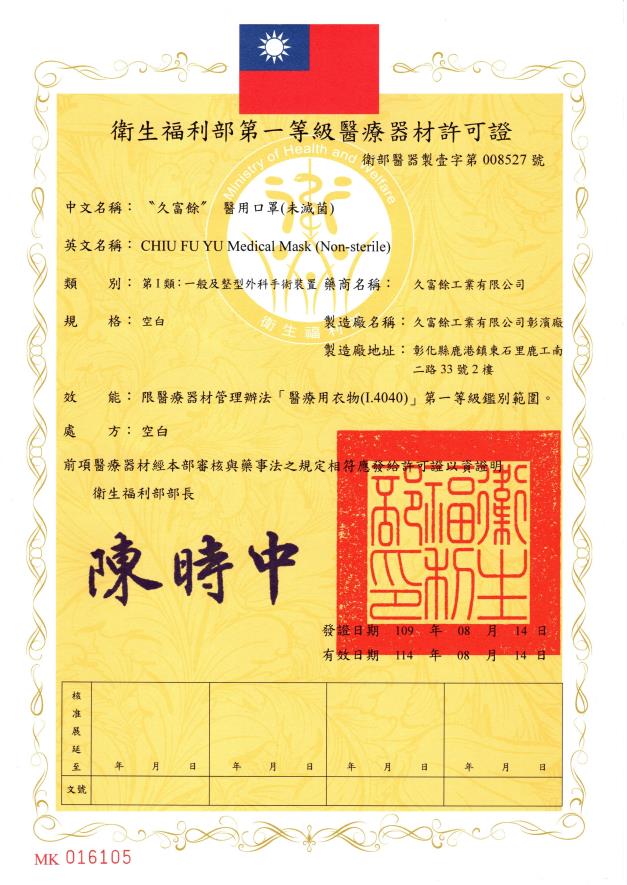

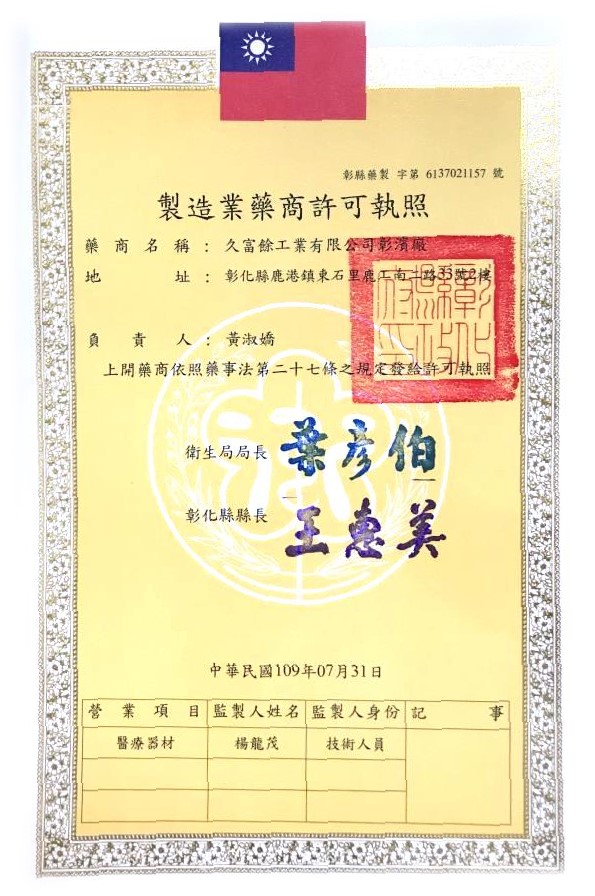

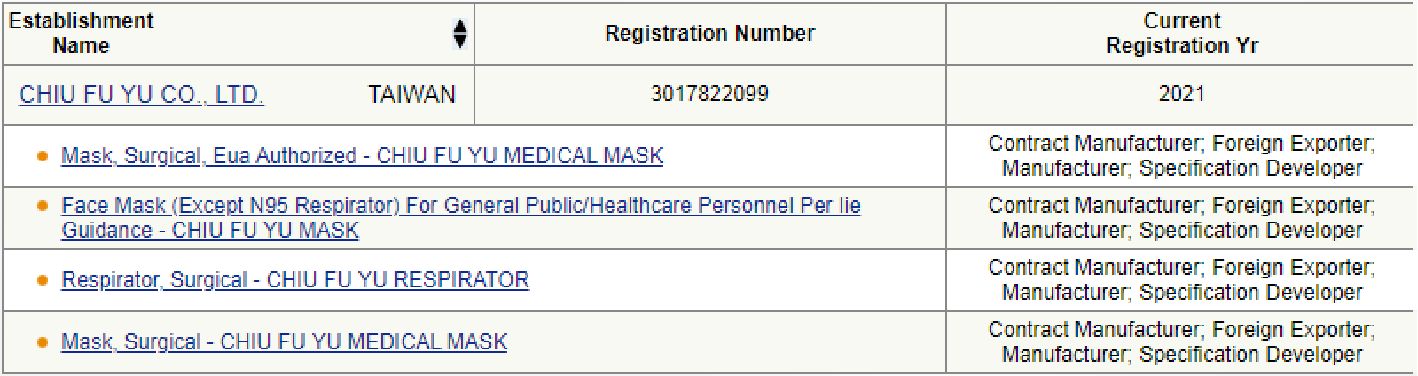

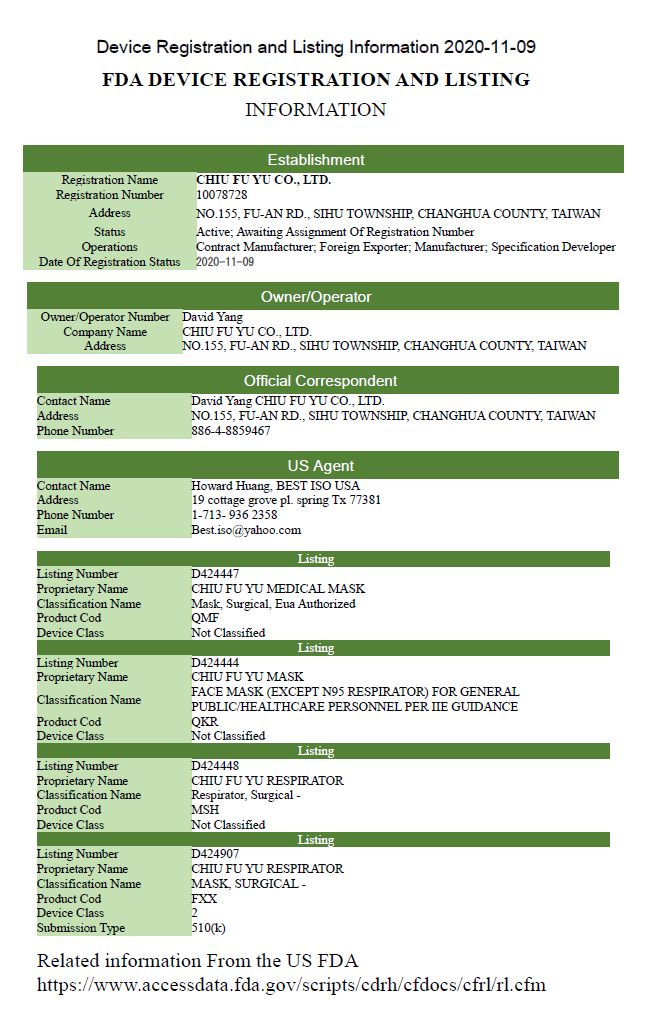

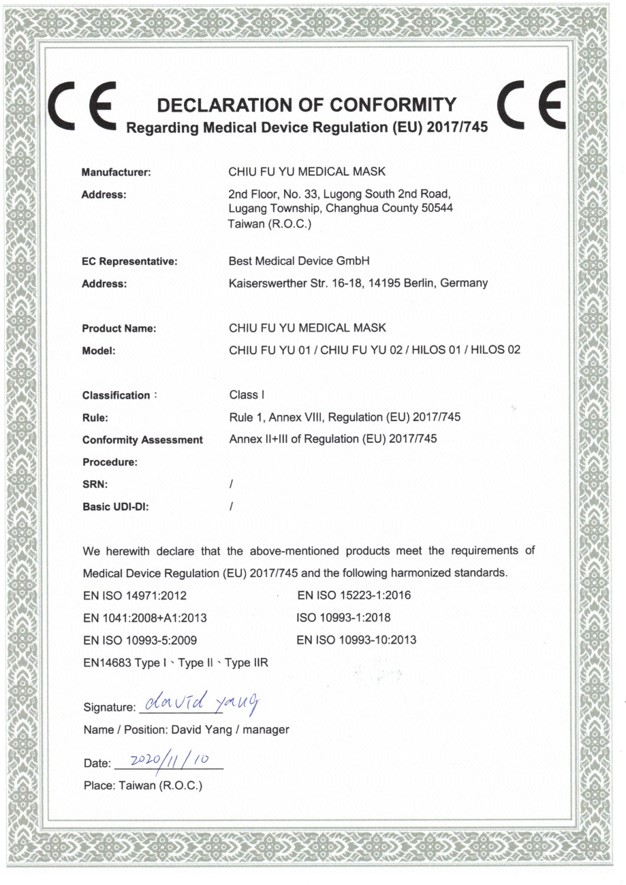

- In July 2020, due to a global pandemic due to the new coronavirus disease (COVID-19). CFY invested more than NT$200 million to set up a clean room and clean room (HEPA-compliant) mask production line. Passed ISO13485:2016 certification, No. 008527, US FDA (10078728), EU CE. The maximum production capacity is 120 million pieces/month.

Location

- Located in central Taiwan, the government plans an industrial zone with the best transportation.

- It is only a 20-minute drive from Taichung Port and Taichung Airport.

- Nearly 61 expressway (3 minutes).

- Near National Highway No. 1 (15 minutes) and No. 3 (15 minutes).

- It lives in a densely populated geographic center.

- Abundant human resources: There are more than ten universities and colleges nearby.

Capacity introduction

Toilet paper 1400mm production line

2-line production line

- Speed: 130 m/min

- Capacity: 1600 boxes/day (100 pumps/bag*10 bags/string*10 strings/box)

- Operator: 7 people / shift

- 2 folding machines, 1 cutting machine, 1 multi-charging machine, and 1 carton sealing machine.

3-line production line

- Speed: 130 m/min

- Capacity: 2400 boxes/day (100 pumps/bag*10 bags/string*10 strings/box)

- Operator: 9 people / shift

- 3 folding machines, 2 cutting machines, 1 multi-charging machine, and 1 carton sealing machine.

Toilet paper 1800mm automatic production line

Extractable production line

- Speed: 200 m/min

- Capacity: 5000 boxes / day (300 pumps / bag * 30 bags / box)

- Operator: 1 person / shift

- 1 folding machine, 1 cutting machine, 1 single charter, 1 cartoning machine, 1 carton sealing machine

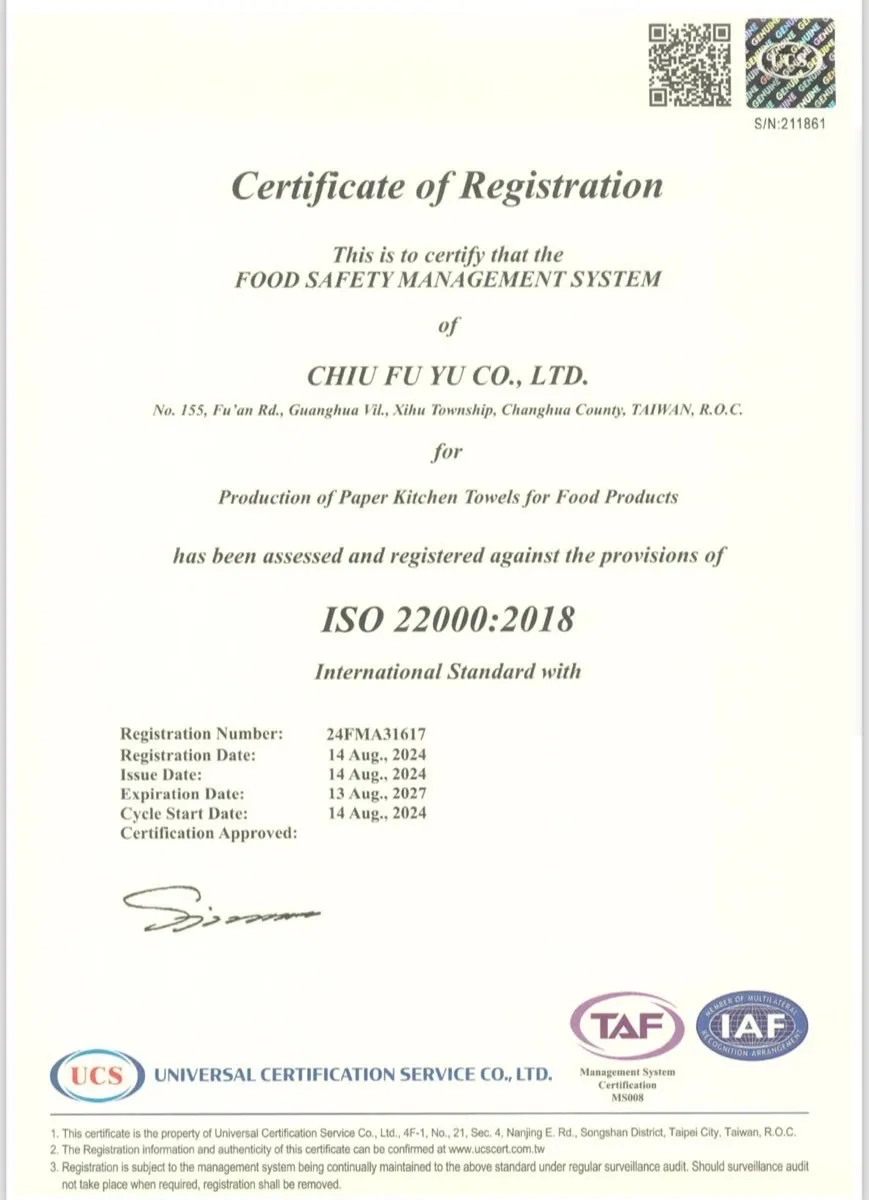

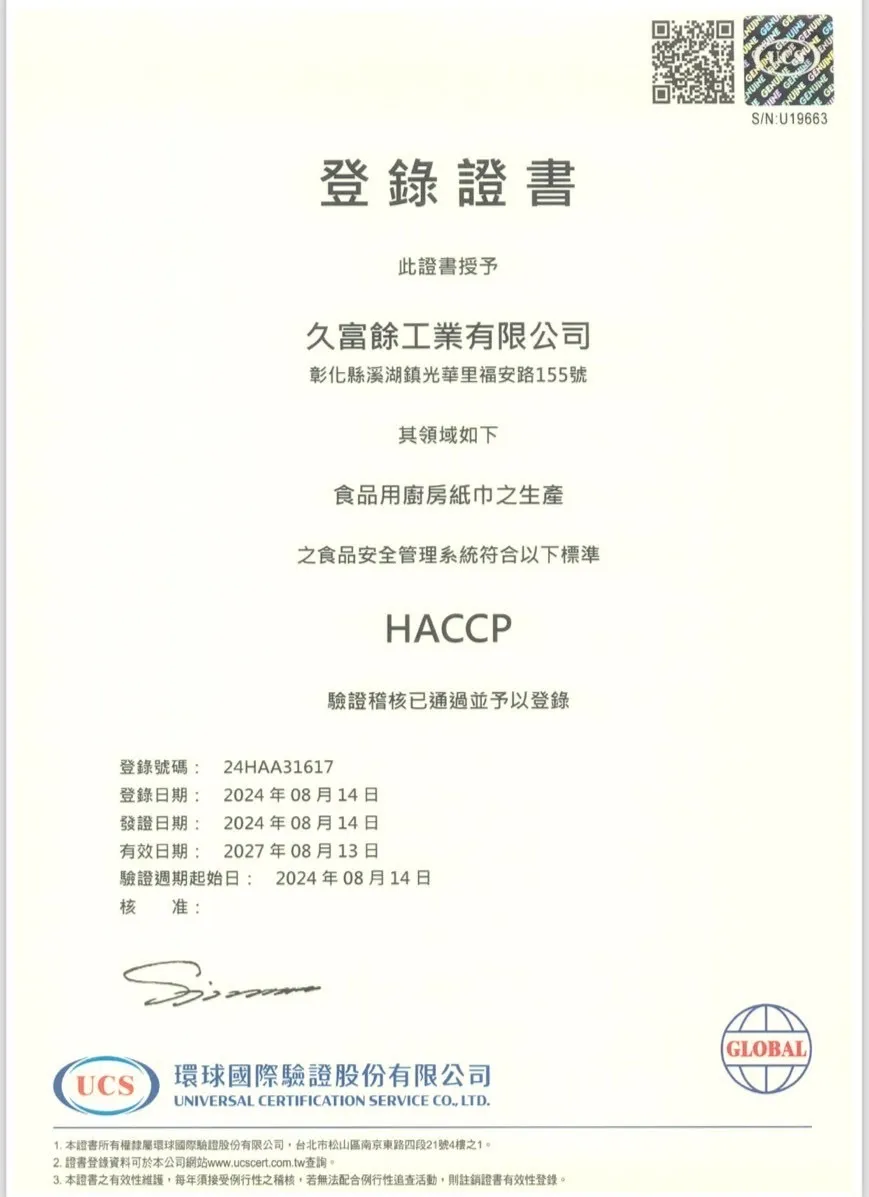

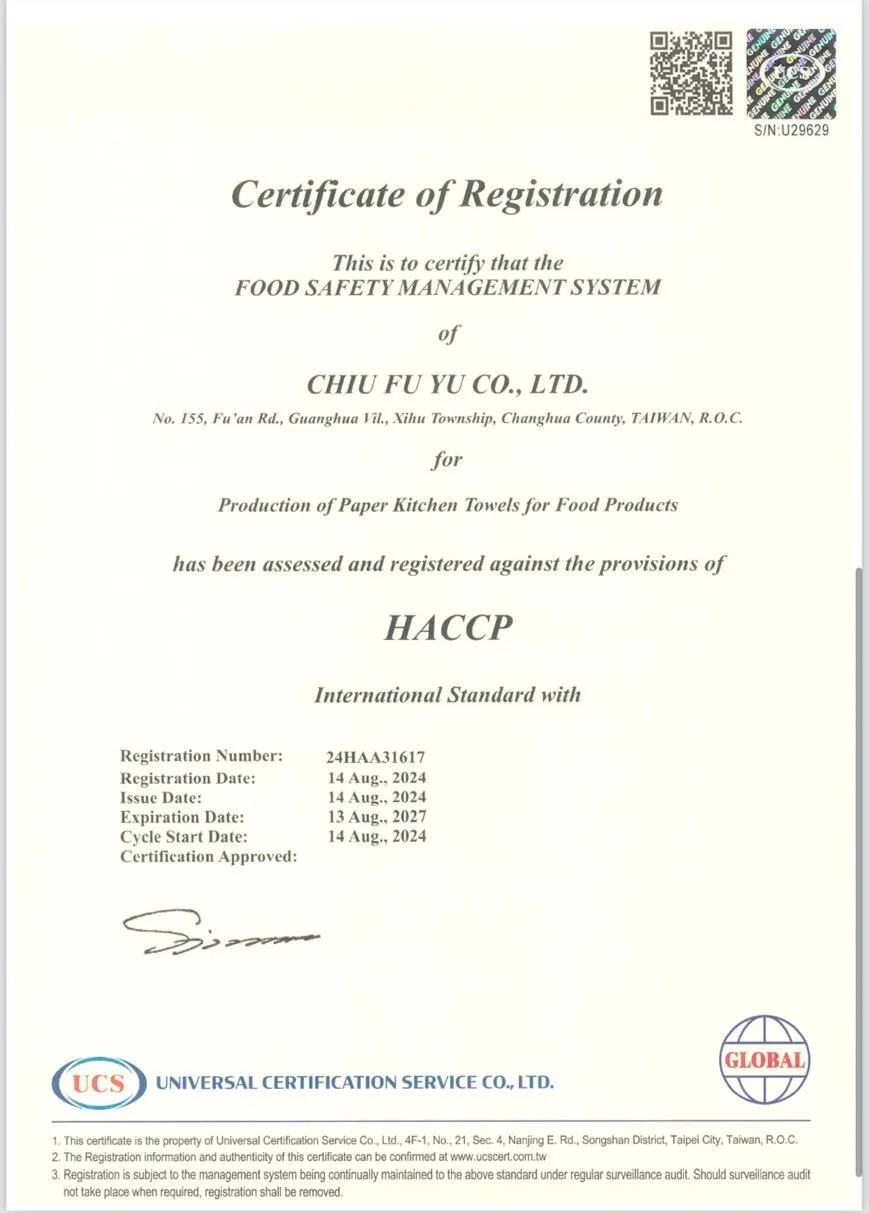

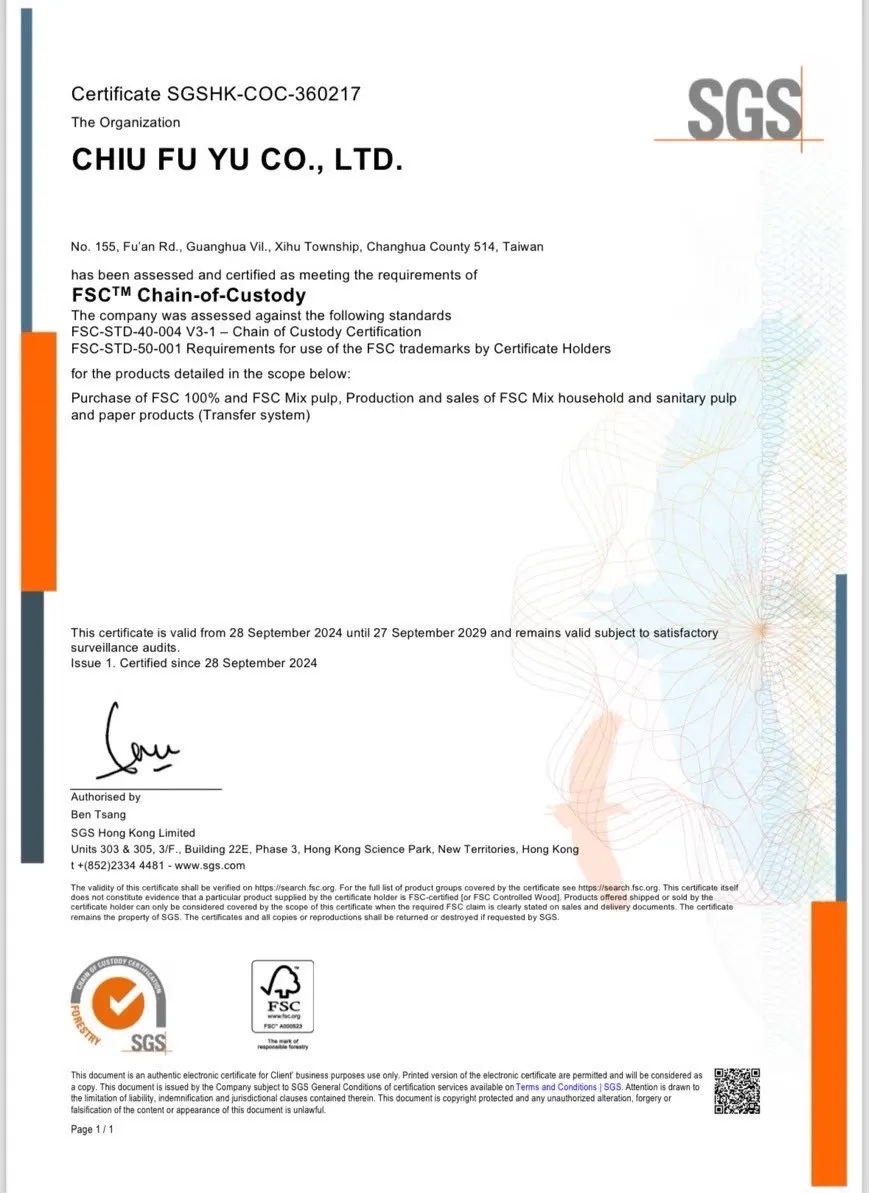

家庭用紙認證

Medical mask production line

Adult mask line

- Line A: Speed 80 pieces/minute *8 units=640 pieces/minute

The production capacity is 900,000 pieces/day. - Line B: Speed 80 pieces/minute *8 units=640 pieces/minute

The production capacity is 900,000 pieces/day. - Line C: Speed 80 pieces/minute *15 units=1200 pieces/minute

The production capacity is 1.7 million pieces/day.

Children's mask line

- Speed 80 pieces/min * 4 units = 320 pieces/min, with a production capacity of 500,000 pieces/day.